PEM Propulsion Efficiency Monitor: The PEM Propulsion Efficiency Monitoring family is a microprocessor based instruments for use with the T-Sense®, TT-Sense®, Fuel Flowmeters and additional inputs. The self-explaining device name focuses the purpose of PEM to improve ship efficiency and fuel cost savings strategy

PEM Propulsion Efficiency Monitor: The PEM Propulsion Efficiency Monitoring family is a microprocessor based instruments for use with the T-Sense®, TT-Sense®, Fuel Flowmeters and additional inputs. The self-explaining device name focuses the purpose of PEM to improve ship efficiency and fuel cost savings strategy

PEM Propulsion Efficiency Monitor – Overview

The S – Keeper 7™ Continuous Emissions Monitoring Systems has been designed to include the T-Sense®, TT-Sense® & PEM outputs in its own algorithm to fulfill the Directive requirements but also to offer a complete overview of ship’s performance. This is the Green Efficiency on Board strategy.

The PEM family is based on different models PEM2, PEM3 & PEM4.

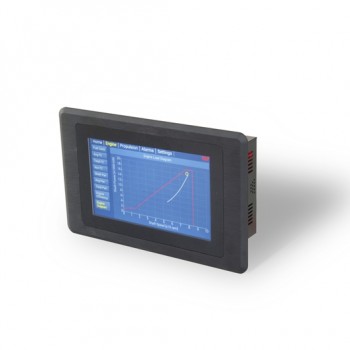

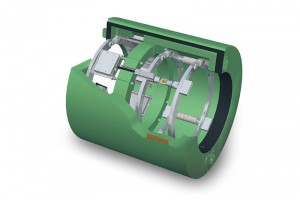

The PEM2 Efficiency Monitor is a microprocessor based instrument for use with the T-Sense® Optical Torque Sensor and TT-Sense® Thrust & Torque sensor. The PEM2 monitors and calculates several parameters within narrow limits. The T-Sense® torque sensor is the measuring instrument providing torque, speed and power as input for the PEM2 . The TT-Sense® additionally provides thrust measurements as input for the PEM2. This completely unique and compact total solution can be used for simple to very complicated configurations. The basis is a touch screen display able to fulfil standard calculations. This display can be extended with a robust Signal Processing Unit for more complex calculations including a large number of extra inputs.

The PEM3 instantly displays torque, speed, shaft power and other selected measuring data. Additional flowmeter signals and temperature sensor (Pt100) signals enable calculation of the engines fuel consumption with optional temperature compensation. In combination with input signals from speedlog or GPS, the PEM3 will calculate the temperature corrected fuel consumption per kW or per nautical mile. PEM3 could manage one additional T-Sense® or TT-Sense® in case of twin screw vessels.

The PEM4 Propulsion Efficiency Monitoring system is a microprocessor based instrument for use with the T-Sense® Optical Torque Measuring System and TT-Sense® Optical Thrust and Torque Measuring System. The T-Sense® is providing torque, shaft speed and power as input for the PEM4 system. The TT-Sense® additionally provides thrust measurements as input. The PEM4 system is supplied with a robust SPU3 Signal Processing Unit, which can be connected to a large number of extra inputs like flowmeters, GPS, speed log, or one additional T-Sense® or TT-Sense® in case of twin screw vessels. In detail the SPU3 can manage a maximum of 12 flow meter inputs in combination with PT100 temperature inputs related to a maximum of 6 consumers.

The SPU3 converts all these input signals to one RJ45 Ethernet signal for monitoring purposes. A RS485 Modbus signal is available for connection to an external system like Alarm and Monitoring System (AMS) or to connect a separate PC running the optional PEM datalogger software.

The SPU3 can be installed in the vicinity of the flow meter(s) and/or booster unit or in the engine control room (ECR). The PEM touch screen can be installed in a control cabinet or control panel in the ECR and/or on the bridge.

Besides checking the status of the torque measurement system and/or flowmeters the PEM system also checks itself continuously for program and configuration data integrity, normal program flow and power supply conditions. All alarm messages will be logged in a dedicated alarm screen.

According to each PEM model here an overview of functions:

• Measurement and display of the torque, thrust, shaft speed and power.

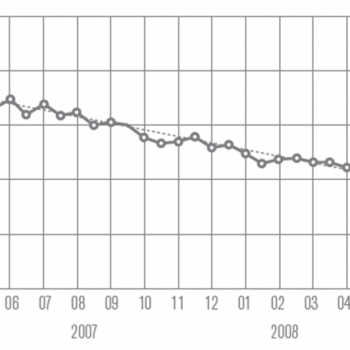

• Calculation of the average shaft power, shaft speed and torque during the last 1, 4 and 24 hours.

• Calculation of the total energy, total revolutions and total CO2 emissions including reset.

• Calculation of the fuel consumption in kg per nautical mile, fuel consumption in kg per hour, fuel

• Consumption in gram per kWh (Specific Fuel Oil Consumption – SFOC)

• average fuel consumption per nautical mile, fuel temperature compensation and calculation of the total mass per fuel type per consumer including reset.

• Calculation of thrust, thrust power quotient, when a TT-Sense® sensor is installed.

• Displaying of parameters, engine load diagram and power/speed diagram.