T-Sense® Torque and TT-Sense® Torque & Thrust devices are based on a non –contact optical measuring systems to be mounted around the ship shaft(s). The purpose of those devices is to offer a deeper view in ship’s engine performances, increasing ship efficiency and consequently leading to a fuel savings up to 5%.

T-Sense® Torque and TT-Sense® Torque & Thrust devices are based on a non –contact optical measuring systems to be mounted around the ship shaft(s). The purpose of those devices is to offer a deeper view in ship’s engine performances, increasing ship efficiency and consequently leading to a fuel savings up to 5%.

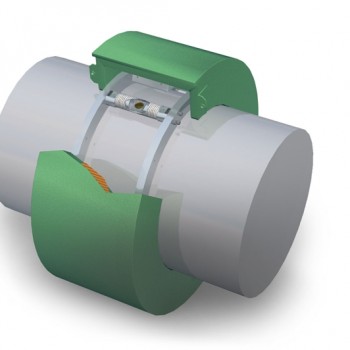

Since the fuel costs will be reduced remarkably, the ROI will only be a few months. VAF’s shaft power torque & thrust meters can be installed easily on both new building and existing vessels for the easiest retrofit strategy. The T-Sense® & TT-Sense® could be mounted around the shaft by the vessel’s crew or shipyard without engineering or commissioning assistance.

T-Sense® & TT-Sense® – Shaft Power Torque & Thrust Measurement –

Overview

Why a Torque measuring system? A torque meter provides you with precise information on engine performance related to consumed energy. By giving instantaneous read-out of torque, speed and power, the effects of operational changes are monitored. Because these effects are measured, you can use your engine-driven installation in its most efficient way. This will considerably reduce your fuel costs, one of the primary cost drivers. The use of a T-Sense® Torque measuring system means efficiency improvement, overload protection and prevention of breakdown costs.

The upcoming of IMO regulations like SEEMP Ship Energy Efficiency Management Plan inspired VAF Instruments to develop the next step in their successful line of sensors: the TT-Sense® Shaft Power Torque & Thrust Meter.

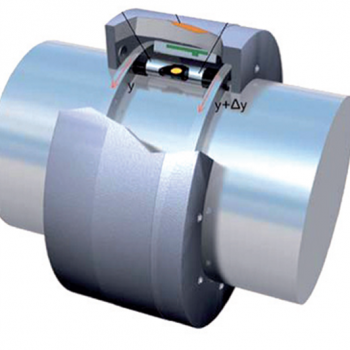

Why a Thrust and Torque Measuring System? The use of a TT-Sense® means getting more insight in your propeller efficiency, hull resistance and vessel pitch optimization. This real thrust measurement is realized by an extremely accurate optical sensor technology. Using the TT-Sense® for measuring thrust, torque results in broad insights in your propeller efficiency, vessel pitch optimization and hull resistance. The TT-Sense® is using the latest techniques to contribute to ship power management.

TT-Sense® Shaft Power Torque & Thrust Meter

2015 Winner – Marine Propulsion – Fuel Efficiency Award

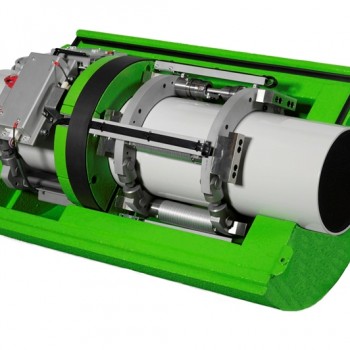

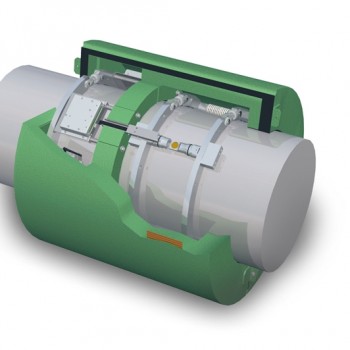

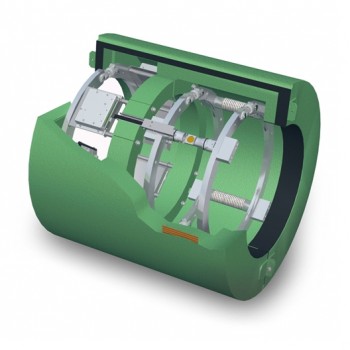

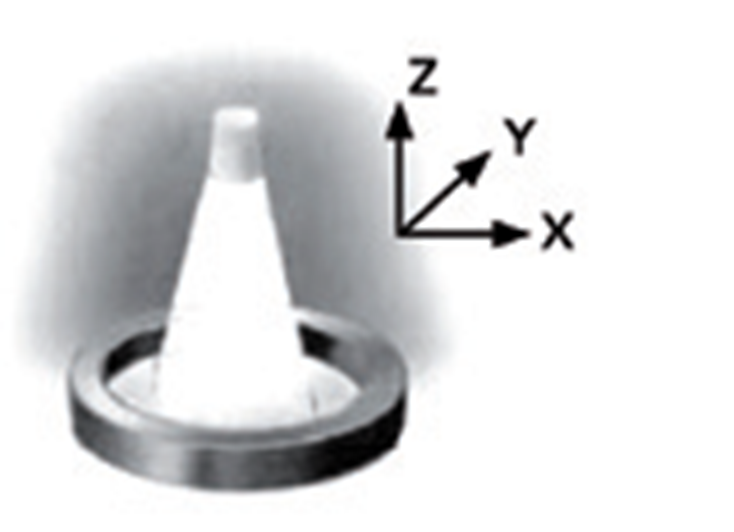

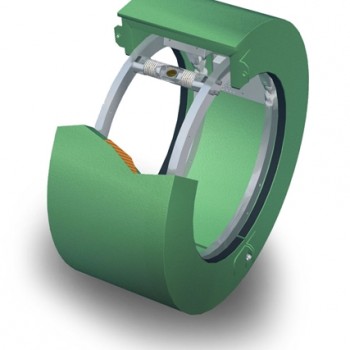

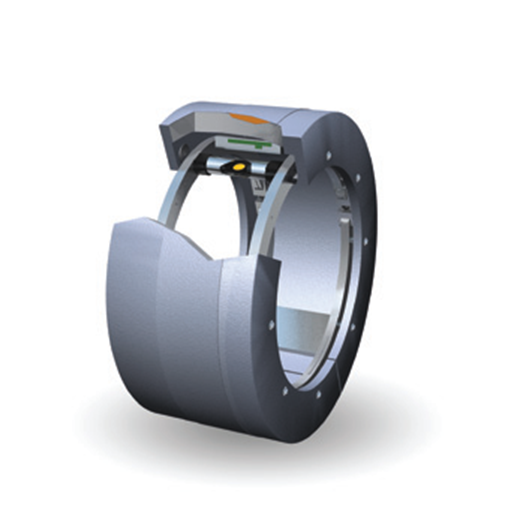

How do they work? The T-Sense® Torque & TT-Sense® Thrust and Torque measuring systems can be mounted on intermediate shafts after the thrust bearing. When a shaft is subject to thrust and/or torque this results in a small strain at the shaft surface. LED’s and extremely accurate optical sensors can detect these small displacements, in both axial and radial directions. The measured values are transferred continuously from the rotating shaft to the stator part through wireless data connection. Power transmission from the stator to the rotating shaft is performed by means of induction. The stator part consists of a power transmission coil, a data signal receiver and a control box equipped with digital or analogue output connections. These outputs can be linked directly to the vessels data network, monitoring- or control system.

The actual torque & thrust measurement is obtained through an extremely accurate optical sensor technology. As a result of this non-contact sensor technology, the T-Sense® & TT-Sense® systems are maintenance free.

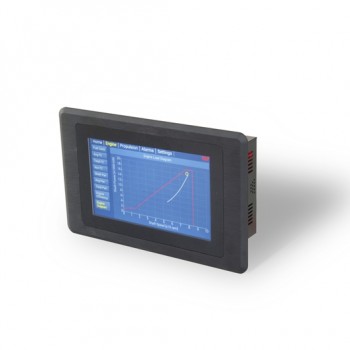

The stator part can optionally be connected to a PEM 2 touchscreen, which displays propeller thrust, shaft power, torque and speed. The PEM 3 Propulsion Efficiency Monitor displays all fuel consumption data, engine load diagram, power and thrust data, etc. With the PEM4 Propulsion Efficiency Monitor, VAF Instruments has developed a completely new monitoring system based on many years of experience and a proven technology, but with modern user friendly electronics. The PEM4 system is able to monitor one or two T-Sense® torque measuring systems together with the fuel consumption of six engines/consumers (max. 12 VAF flowmeters).The PEM4 Propulsion Efficiency Monitor is very easy to use because of its menu structure. All measured and calculated data can be read directly from the screen, on which they are displayed as both figures and graphs. The PEM4 system helps owners to improve ship efficiency and to monitor engine performance in a very convenient way.

T-Sense® Standard Configuration. The standard T-Sense® system is based on torque and speed measurement, out of which performed power on the shaft can be calculated. The system can be extended with the following modules:

- energy consumption

- actual fuel consumption per engine, per genset or boiler

- specific fuel consumption per kW (SFOC of main engines)

- fuel consumption per nautical mile

- total power calculation

For these extensions other signals can be fed to the PEM4 system, such as fuel flows, fuel temperature, speedlog, GPS or shaft generator power level. Together with the standard torque, speed and power signals, the PEM4 system will be able to calculate the desired data.

The S – Keeper 7™ Continuous Emissions Monitoring Systems has been designed to include the T-Sense®, TT-Sense® & PEM outputs in its own algorithm to fulfill the Directive requirements but also to offer a complete overview of ship’s performance. This is the Green Efficiency on Board strategy.

T-Sense® advantages

- Fuel saving by efficiency improvement on ships

- Preventing damage and overhaul costs

- No engineering and commissioning assistance needed at installation

- Only one communication cable to the bridge

- No time consuming mounting of strain gauges

- Competitive pricing and delivery times

- Robust design, maintenance free, no wear no tear

- Worldwide service network of certified VAF agents

TT-Sense® additional advantages:

- Propeller thrust and hull analysis possible

- Pitch optimization

- Cavitation detection

- In line with SEEMP Ship Energy Efficiency Management Plan regulation

TT-Sense® Shaft Power Torque & Thrust Measurement – Overview