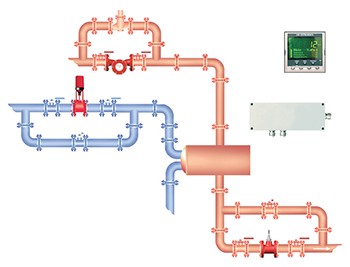

Viscosity measurement and control systems are used for continuous in-line measurement and control of viscosity of many liquids. Specially designed for fuel oil applications, it is used for diesel engines on ships and in land based power plants. VAF Instruments expertise in this field resulted in a unique patented, superior measuring principle; ViscoSense®.

Viscosity measurement and control systems are used for continuous in-line measurement and control of viscosity of many liquids. Specially designed for fuel oil applications, it is used for diesel engines on ships and in land based power plants. VAF Instruments expertise in this field resulted in a unique patented, superior measuring principle; ViscoSense®.

Why Viscosity is an essential parameter for Ship Efficiency?

A large variation in the quality and composition of fuel oil, makes the behavior of the fuel oil at higher temperatures difficult to predict. An optimal viscosity is needed for the best possible atomization of HFO in the engine, so the fuel will be burnt completely without remaining deposits. The measurement and control of the viscosity ensures an improved combustion efficiency, preventing engine damage and reduces cost of maintenance. Viscosity control contributes to a green environment.

Viscosity Control for fuel saving and ship efficiency

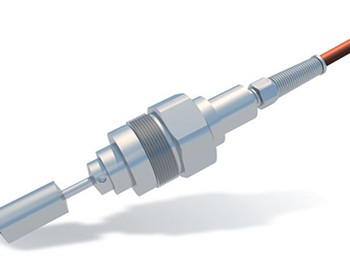

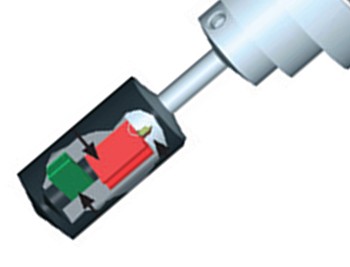

The VAF Instruments ViscoSense® is a viscosity sensor with a unique operating principle. The patented measuring principle is based on rotational vibration of a pendulum in liquid. The damping of this electrically controlled vibration is directly related to the viscosity. The ViscoSense® achieves the most accurate viscosity measurement possible. A built-in temperature sensor is used to measure the temperature at the same location where viscosity is measured. ViscoSense®2 is able to measure inline the actual dynamic viscosity of a large range of liquids. Due to the operating principle based on a torsional vibration, the measurement is insensitive to unwanted external influences.

Flow velocity, flow direction and pulsations have no effect on the sensor operation.

The robust built sensor is designed to operate under the most difficult conditions in which a faultless and stable viscosity measurement is required.

ViscoSense®: a world of benefits.

Cost saving:

•optimizes burning efficiency and fuel consumption

•reduces engine maintenance/overhaul costs

•no moving parts, therefore low operating costs are ensured

•the smooth edged pendulum is practically insensitive to adherence preventing local servicing costs

User-friendliness:

•no preventive maintenance required because ViscoSense® has no moving parts

•the compact light-weight construction is easy to install in new and retrofit applications

Product quality:

•calibrated for life which makes re-calibration in the field unnecessary

•all SS-316 pendulum does not corrode and is durable

•provides better emission control to minimize air pollution

Unique product features:

•ISO 9001 quality assurance certification

•continuous in-line viscosity control

•resistant against line pulsations

•long term accuracy and reproducibility

•type approval certificates from all major classification authorities

Today, VAF Instruments is world-market leader in fuel viscosity control.

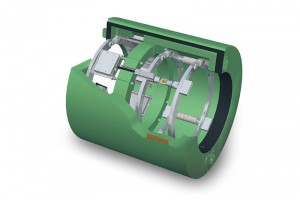

Since 1962 VAF Instruments has manufactured the well-known VAF Viscotherm® product line. In the year 2000, VAF has introduced the ViscoSense® and in 2007 the ViscoSense®2 has been launched which has been followed up by the ViscoSense®3 in 2014.

Are you a loyal customer of VAF Instruments? Have you still installed our legendary Viscotherm® system? Please consider Retrofitting from Viscotherm® to ViscoSense® , a specific brochure is available.

More than 30,000 systems have found their way to ships and industrial plants all over the world. You’ll find VAF service facilities in more than 40 countries in principal harbors, industrial and shipbuilding areas of the world.

VAF Instruments Customers never sail alone.